ABOUT NEOTECMAN

Welcome to Neotecman: Innovators in Hot Forging

Neotecman is an innovative engineering company specializing in the production of hydraulic presses and furnaces, revolutionizing the hot forging industry with a cutting-edge production concept that outpaces traditional forging systems in competitiveness and technology.

Our company is strategically situated in an industrial hub just 100 km from Barcelona, boasting over 30 years of industry expertise.

NEOTECMAN solutions encompass a wide range of equipment and services, including:

- Advanced furnaces for precise bars heating

- Efficient bar cutting and feeding systems

- High-performance servo-hydraulic hot forging presses

- Customized tooling solutions: from design and manufacture to rigorous testing

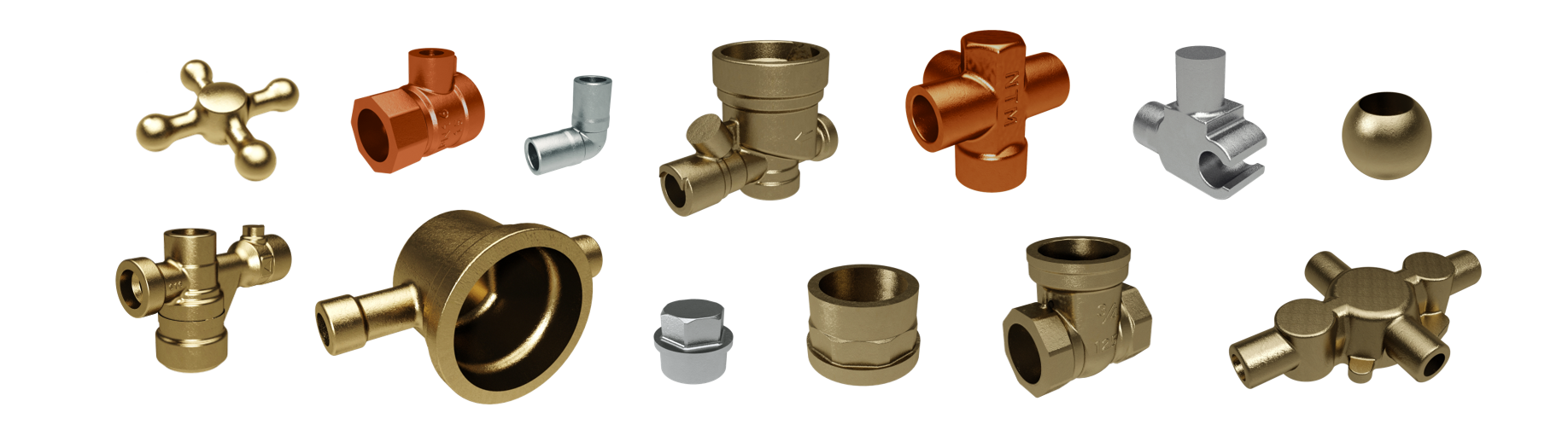

Our brass hot forging systems are tailored to meet the demands of diverse sectors and applications, including:

- Heating system fittings: HVAC fittings,fittings for gas applications, radiators and central heating fittings, gas plumbing,

- Fittings for water supply: water meters, water plumbing, plumbing fittings, valves for water (ball o gate valves for water, elbows, Tee fittings, water intake, plumbing, strainers)

- Fittings for hydraulics

- Fittings for pneumatics

At Neotecman, we’re not just manufacturers; we’re pioneers in the world of hydraulic, flashless hot forging equipment for non-ferrous materials (brass, aluminium and copper). Our commitment to innovation has made us the industry leader, setting new standards for excellence in hot forging technology.

Resources Optimization

We understand the importance of resources optimization in today’s world. That’s why Neotecman is dedicated to meeting the requirements of tomorrow. What makes Neotecman truly unique is our “All-in-One” technology. We’ve successfully integrated all the necessary plant components for hot forging into a single, compact machine. This innovation delivers:

- Material Optimization: Reducing material waste is a priority, ensuring a more responsible use of resources.

- Space Utilization: Our compact equipment optimizes floor space, making your operations more efficient.

- Operator Productivity: Neotecman technology enhances operator efficiency, reducing the need for extensive training.

- Time Saving: We minimize production time, helping you meet tight deadlines.

- Noise Reduction: Our equipment is designed to minimize noise pollution in your workspace.

One Machine, One Service, One Computer System

Neotecman’s approach is all about efficiency and simplicity. We offer:

- One versatile machine to handle all your hot forging needs.

- One comprehensive service to support your operations.

- One efficient computer system for seamless workflow management.

Customizable Billet Cutting

Billets are cut after heating in a gas or induction furnace, guaranteeing minimal material waste.

Say goodbye to the hassle of pre-sawn billets and rigid planning. With Neotecman, billets length can be customized during production, offering you unparalleled flexibility in your operations.

Streamlined Operation in Two Steps

Operating Neotecman equipment is as simple as it gets. We’ve streamlined the hot forging process into just two steps:

- Load a bundle of bars.

- Collect the pressed, flashsless parts ready for machining.

Contact Us Today

Ready to experience the future of hot forging? Visit our website to learn more about our products and services. If you have any questions or need further information, don’t hesitate to contact us. Connect with us on social media to stay updated on our latest innovations.

Your journey towards revolutionary hot forging begins with Neotecman.

Nowadays the company exports the knowledge and products to the five continents. Neotecman is committed to the future; we are convinced that THE BEST WAY TO PREDICT FUTURE IS TO INVENT IT.

Neotecman’s Vision is to become the leading designer and manufacturer of the most innovative, compact and versatile range of servo-hydraulic driven forging systems for non-ferrous metals, fully satisfying our Customers production requirements.

Neotecman’s main Mission is to meet the special needs of each Customer by offering the highest product quality and accurate movements control of furnace, bar cutter and press. We are focused on building long-term business relationships with our Customers, providing customized approach on every project, based on cutting-edge technology and continuous research and improvement.

ORIGINS

The history of the company begins 40 years ago with the family business Metalúrgica Domingo S.A., founded in 1981. The company specialized in traditional forging of brass products such as valves and fittings. One of the founders, Manel Domingo, worked with his father. His restless mind never stopped inventing the automation of traditional mechanical presses, the only ones on the market back then. Manel looked for ways to improve, speed up and automate the various stages of stamping, until he was able to transform the established presses into a completely new and innovative concept. These modified machines have generated a lot of interest from other brass manufacturers.

And at some point, Manel decided to devote himself exclusively to the production of presses, instead of brass parts. He proposed founding a new company called Neotecman to Carles Esteve, who had been working as a stamping machine maintenance technician at Metalúrgica Domingo S.A. for 10 years. Carles was fully engaged in electronics, hydraulics, pneumatics and mechanics at the plant. It was a radical and bold decision, but Manel took a chance and sold Metalúrgica Domingo S.A. Thus, in 2004, the world saw the first punching system including furnace, bar cutting system and press officially manufactured by Neotecman. It was the R.28, with a single vertical punch to handle bars up to 28 mm in diameter. After some years, a much more complex press was developed and manufactured, which already had 4 horizontal and 1 vertical punches, a model which still has its predominant place on our catalogue and of course, on the market.

WORLDWIDE REFERENCES