H3.32 The first step

DOWNLOAD TECHNICAL FEATURES H3.32

PRESS

H3.32 The first step

This system is an automatic hydraulic press designed to be very flexible for production changes, and compact including all-in-one, a combustion furnace for the heating of 4 metres whole brass bar, a shear cutting device for billets, a manipulator to feed the hydraulic pressing unit, as well as a finished-parts unloader, all completely automated and computerized.

Achieving a flashless stamping on every occasion saves the subsequent clipping operation and reduces the size of billet required adding further to the savings which are made by using the NEOTECMAN method.

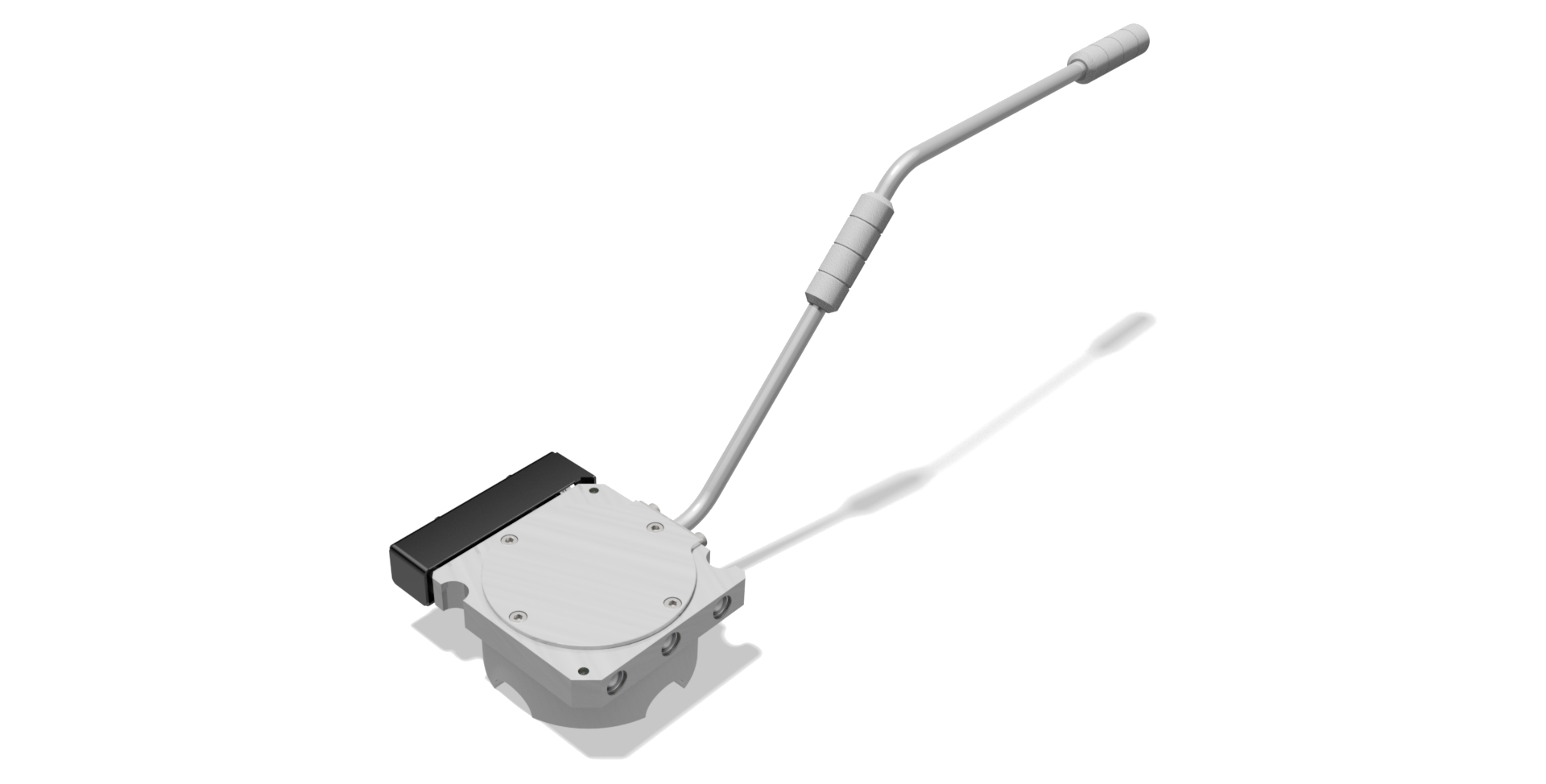

The machine has 3 horizontal punches, regulated independently by an industrial PLC which allows to control the forward and backward movements of the punches inside the die with different delays (1/100 seconds) as well as independent pressures in order to deform the brass according to the final shape of the forged piece. This will save machining process in terms of time as well as tooling wear.

This press is designed to be economical, with reduced dimensions for installation in a clean environment with a noise level lower than 85 db. Also, it can be installed near CNC machines thanks to the lack of vibrations during production.

In addition, this solution is equipped with the latest innovations in terms of IT and control tools as standard that allow real time communication between the machine and the operator from anywhere.

| FORGING FORCE | 100t |

| PUNCHES | 3 horizontal |

| PRODUCTION (empty) | From 500 to 3.400 parts/hour |

| BAR DIAMETER | From 12 to 32 mm (From 0.47 to 1,26 in) |

| BAR LENGTH | Up to 4.000 mm |

| DIE DIMENSONS | 205 x 205 mm |